RESEARCH & DEVELOPMENT

BUILDING A BETTER FUTURE THROUGH CONVERGENCE

Technical R&D

We are striving to develop technologies that will be the foundation for future industry development.

Through provision of a variety of differentiated products and solutions, we will make a maximum contribution to the stable growth and development of our customers.

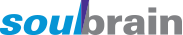

Semiconductor

The semiconductor industry is an area in which process miniaturization is emerging as an important issue. At Soulbrain, we are developing diverse products which can provide optimized solutions for process miniaturization.

Etchant / Cleaning / Stripper etc.

- High Selective Nitride etchant(SiN/O Selectivity) for 3D gate

- High Selectivity Oxide Etchant, HF/BOE, Cleaning Agent & Stripper 개발

CMP Slurries : Ceria slurry, Silica slurry, etc.

- High Planarity Slurry(ILD/IMD, CST-S22), STI(DRAM & Flash), Wet Nano Ceria(DRAM&NAND)

- Cu Barrier Slurry(Alkali, Acidic), W Slurry(2nd step & buffing step)

- Polishing slurry for Packaging(TSV), Nitride/Poly-Si CMP slurry

Slurry for LED and other processes: Bare Silicon Slurry

CVD/ALD Materials

- High-k Precursor : ZAC (Zr), ZEBRA (Zr), Z03 (Zr), HAC (Hf), H03 (Hf)

- Dielectric precursor : HCDS (Si), SBBP01 (Bi)

- Metal precursor : TiCl4 (Ti), TBTDET (Ta), Mo precursor

- New memory precursor : Ge07~12 (Ge), Te01 (Te), Sb01 (Sb), SBIP01~04 (In), SBGP01~03 (Ga)

- Advanced deposition materials

· growth inhibitor (ASP, NSP)

· growth activator (TSI07, SB305)

· Area selective deposition materials

· Atomic layer etching materials

Display

Soulbrain is focused on the development of special chemical materials for dramatic cost reduction, along with the development of various new products which are being used in the next-generation display industry.

Etchant for OLED & TFT LCD

- Cu Etchant (for H2O2 & non-H2O2)

- BOE (Si Etch or Cleaning)

- Pixel Etchant (ITO, IZO, IGZO)

- 기타 metal Etchant (Al, Mo, Ag, etc.)

Thin Glass

- Glass Etching Chemical & Glass Slimming Process

Secondary Battery

We are continuously progressing with R&D in the fields of secondary battery materials and next-generation large capacity HEV and EV electrolytes.

Electrolyte for IT, xEV, ESS

- HP(High purity) Grade Solvents : Over 99.9%

- HP Grade Additives : Over 99.0%, Additives are available for customer’s demand

- Solutes : Guaranteed solutes for electrolyte

- Cylinder type : 1L bottle, 18L/200L cylinder

Research Area_ Cathode & Anode materials

- Lead Tap

Electrolyte development

- High Ni Cathode : Gas suppression, Low resistance

- High Si Anode : Long cycle life

- NMX, LMR, Mid-Ni : High Voltage

- LFP : Low temperature, High power

Next generation development

- Sodium-ion battery : Long cycle life, Gas suppression

- Solid-state electrolyte : high ionic conductivity

Functional Materials

We are carrying out R&D on various functional organic materials capable of matching the fast changing market requirements.